Struvite Phosphate Removal

CNP Technologies AirPrex™ – A Complete Solution to the Struvite Problem

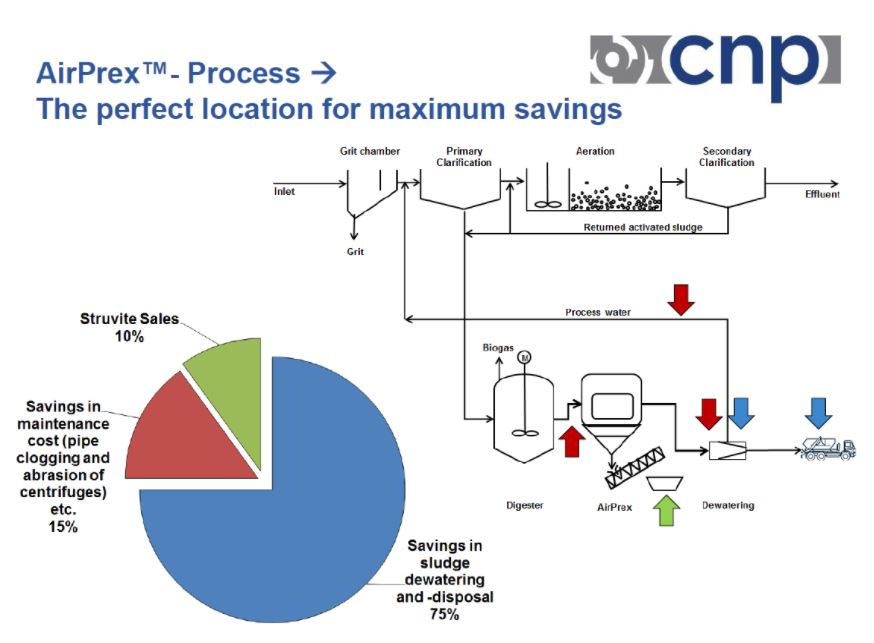

AirPrex™ is a complete sludge optimization and phosphorus recovery system that’s installed between anaerobic digestion and sludge dewatering steps. Controlled struvite precipitation is regulated by air stripping in the AirPrex™ reactor with the addition of a magnesium chemical product. The combination of biological phosphate elimination and the AirPrex™ system achieves unrivaled effectiveness in terms of wastewater dewatering efficiency and cost savings.

Find out more

Struvite Causes Reduced Sludge Dewaterability and Wastewater Treatment Plant Capacity

In wastewater treatment plants with biological phosphate elimination, high phosphate concentrations occur in the digester’s anaerobic environment.

As a result, struvite (or MAP: magnesium ammonium phosphate) builds up inside the pipes, pumps and process equipment, causing problems including:

-

-

- Reduced plant capacity due to decreased flow through the digester’s pipes

- Reduced dewatering efficiency due to increased water bounding effects in the sludge by high phosphate levels

- Increased phosphate loads in the return liquor, which leads to a less efficient phosphate-elimination process and causes crystallization problems in pipes and pumps

-

How AirPrex™ Optimises the Sludge Treatment Process Like No Other System

Until now, the main methods of struvite removal have been:

-

- Costly, recurring chemical treatment

- Phosphorus removal after dewatering

Unlike these other systems, AirPrex™ is a complete sludge optimization and phosphorus recovery system that’s installed between anaerobic digestion and sludge dewatering step. The conditions for controlled struvite precipitation are set by air stripping in the AirPrex™ reactor with the addition of a magnesium chemical product. The combination of biological phosphate elimination and the AirPrex™system achieves unrivaled effectiveness in terms of wastewater dewatering efficiency and cost savings.

AirPrex™ Removes Struvite while Significantly Improving Efficiency

The AirPrex™ process has been designed to produce maximum return on investment and make a significant impact on your treatment plant’s cost of operations. The elimination of struvite through this unique process leads to a 90 to 95 percent phosphate reduction in the returned liquor (up to 15 percent related to the incoming P-load).

-

-

- Reduce Polymer by up to 30%

- Reduce Disposal Costs by up to 20%

- Reduce Phosphorus Recycle Load by up to 90%

- Reduce Maintenance Costs by up to 50%

- Increase Revenue up to 10% from Fertiliser

-