Primary

Clarification processes are commonly used in as the first stage of solids separation in water, sewage and industrial treatment systems. Hydroflux Epco have provided over 330 clarifier units throughout Australasia, Middle East and UK with installations dating back to 1962.

Hydroflux Epco have extensive expertise in the design and construction of primary clarifiers for:

- Primary sedimentation for sewage treatment

- Primary clarification for water treatment (river water, dam water, desalination)

- Primary clarification for industrial water treatment (mining, food & beverage, tunnelling, construction and power industries)

Find out more

Key Advantages include:

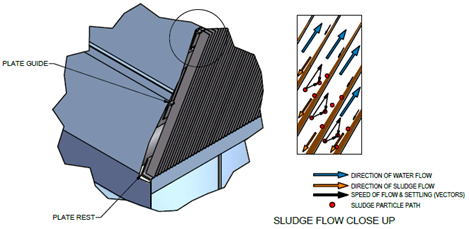

- High surface area lamella pack design

- Proven robust mechanical design with over 330 clarifier installations

- Heavy duty designs

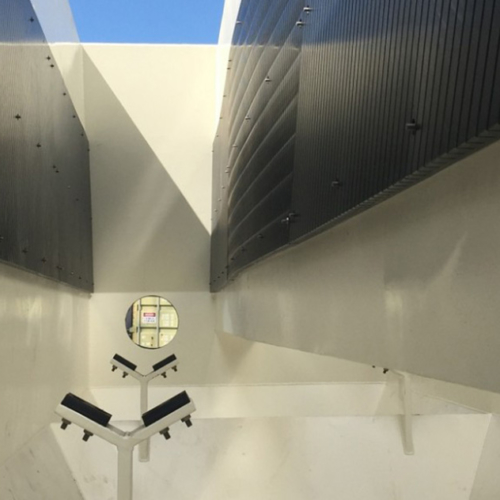

- Proven effective bottom sludge removal systems

- Elimination of dead zones

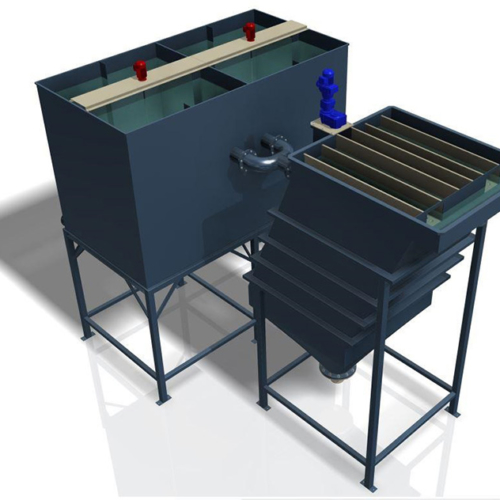

A number of designs and configurations are available, these include:

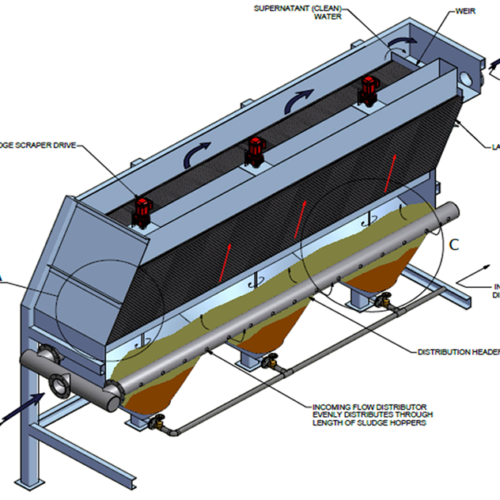

- Free standing tank with single or multiple sludge hoppers

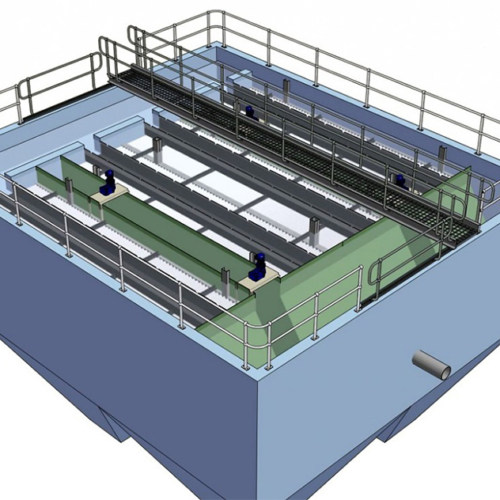

- Concrete tank with integrated sludge removal systems

- Lamella upgrades to existing circular clarifiers

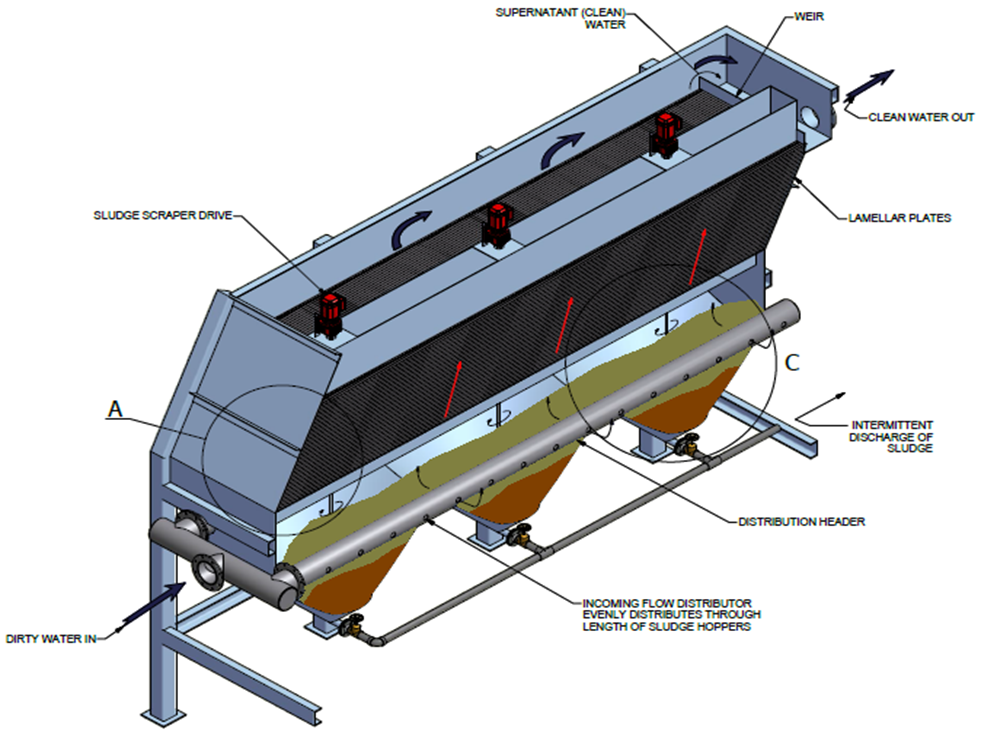

The HiFlowTM lamella separator is a high rate solids separation process that has 1/10th of the physical footprint as compared to conventional circular clarifiers. It is used as a primary and secondary clarifier in sewage, primary clarifier in water treatment and primary clarification of industrial wastewater.

Hydroflux Epco have extensive expertise and references for clarification/lamella technology as follows:

- Over 330 clarifier systems manufactured since 1962

- Highly effective plate pack surface area

- All stainless steel lamella pack construction

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®)

- Laminar flow conditions

- Free standing design in steel construction

- Concrete tank designs for larger applications

A series of inclined lamella plate packs are used to increase the effective surface area of the unit and to overcome hindered settling.