Lime Saturators

LimeFlo™ Lime Saturators – Designed and Manufactured Locally

Lime Saturators are used to dissolve lime solids in water treatment processes, producing a clarified, saturated lime solution while minimising impurities and optimising lime utilisation. Hydroflux Epco have extensive expertise and references for Lime Saturators/Clarifiers with over 330 clarifier systems manufactured since 1962.

Key Benefits

- Improved lime utilisation, reducing chemical costs

- Consistent production of clear lime water

- Enhanced process efficiency and reliability

- Reduced maintenance requirements

- Optimised sludge management, reducing waste

- User-friendly operation and low energy consumption

Why Use Lime Saturators?

The most cost-effective and commonly used form of lime is hydrated lime, or calcium hydroxide (Ca(OH)₂), which is challenging to handle in all its forms and inevitably contains impurities. Traditionally, lime has been added to treat water as a dilute slurry, which introduces impurities directly into the water and increases turbidity. Over time, these impurities accumulate in pipelines and storage tanks, requiring maintenance strategies to be put into place

In New Zealand, industrial-grade lime has an 85% purity. Consider a 100 MLD (million litres per day) capacity plant requiring 30 mg/L of hydrated lime. If 85% purity industrial lime is used, approximately 1,100 tonnes per year of lime would be consumed, depositing nearly 165 tonnes per year of impurities that must eventually be removed from the system. Using premium grade lime with 94% purity can help mitigate this issue to some extent, however, this comes at a higher cost and still contains impurities that need to be dealt with.

The lime saturator is a process unit designed to make saturated lime water and remove and manage impurities before dosing into the water or wastewater stream.

LimeFlo™ Overview

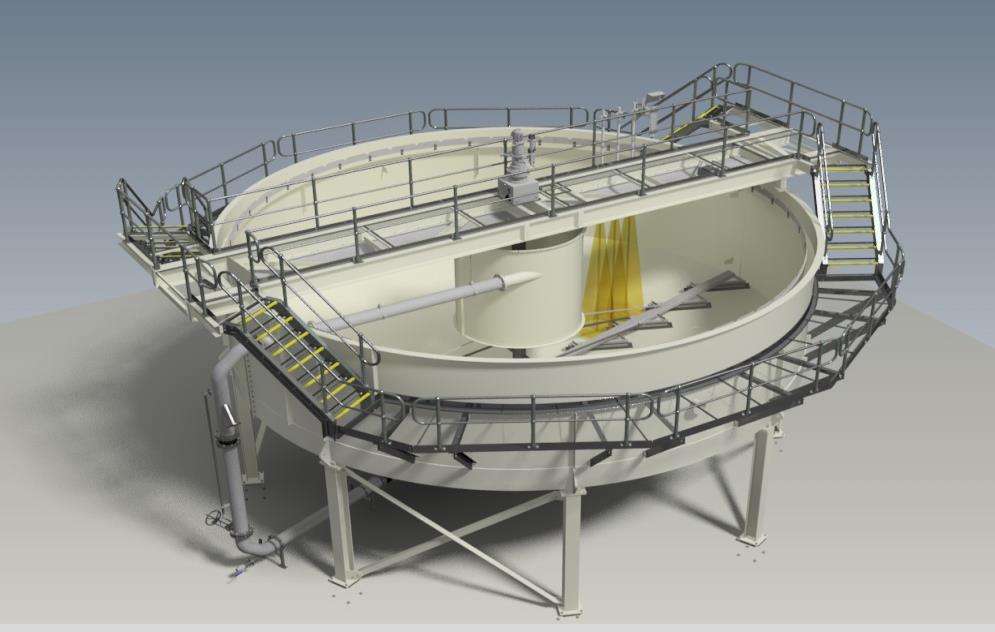

The LimeFlo™ Lime Saturator from Hydroflux Epco efficiently produces clarified lime water from lime slurry for effective pH and alkalinity control in water treatment processes. The saturator comprises a tank featuring a central feedwell, V-notch weirs, a sludge hopper, and an integrated CircPro™ recirculation system. Lime slurry, combined with dilution water, enters through the CircPro™ manifold into the feedwell, evenly distributing across the tank for optimal separation. Clarified lime water rises, overflowing into a launder channel to storage, while heavier impurities and unused lime solids settle to form a sludge bed at the tank’s base.

The CircPro™ recirculation system continuously recycles sludge from the bottom hopper back to the feedwell, enhancing lime utilisation and improving overall process efficiency. A sludge rake fitted with stainless steel blades and neoprene squeegees maintains gentle agitation, preventing sludge compaction and guiding solids towards the central hopper. Excess sludge is periodically removed by dedicated sludge wasting pumps to maintain the desired sludge bed level, ensuring consistent quality and clarity of lime water output.

Discover How LimeFlo Lime Saturators Can Enhance Your Treatment Processes

Contact Hydroflux Epco today to explore how LimeFlo Lime Saturators can significantly enhance your water treatment processes. LimeFlo systems deliver precise lime water production with superior lime utilisation, ensuring consistent water clarity and reducing chemical costs. Reliable and easy to operate, LimeFlo saturators require minimal maintenance and are designed for long-term, dependable performance.

To further optimise your water treatment system, Hydroflux Epco offers comprehensive turnkey solutions—from design and engineering to installation, commissioning, and ongoing support—to meet your specific site requirements.

Get in touch with Hydroflux Epco today.