Free Standing Design

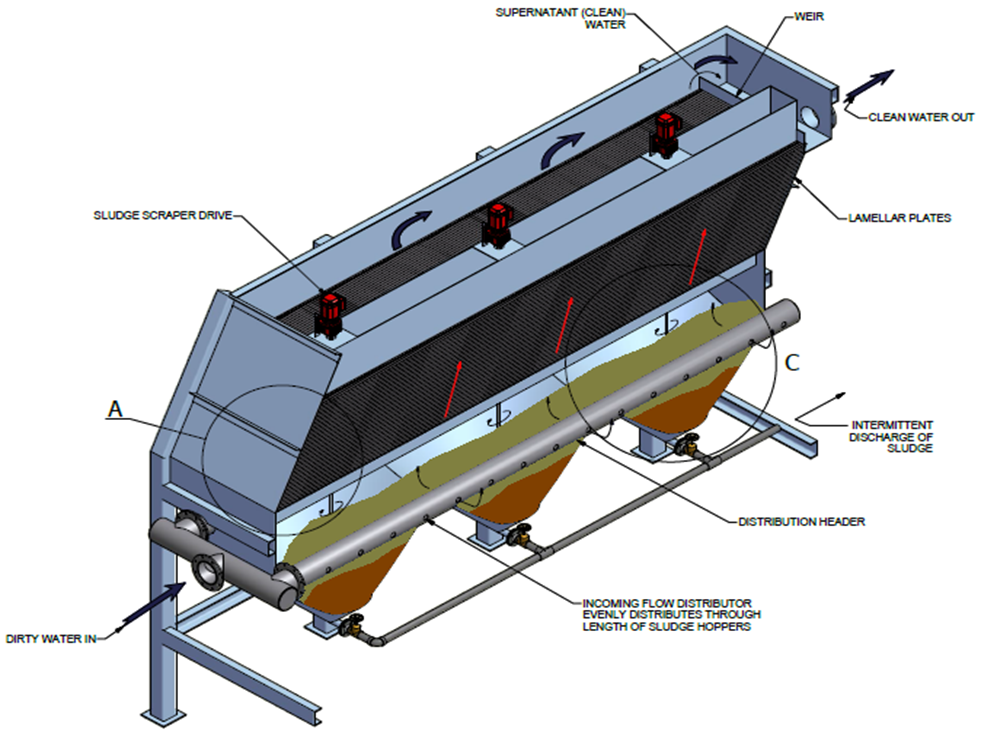

HiFlowTM can be provided with a single or multiple sludge removal hoppers. In larger systems the use of multiple hoppers results in a reduced tank height and hence a cost benefit.

The free standing tank option is ideally suit to capacities under 3MLD per unit. The upstream chemical pre-treatment equipment can be provided as an integrated packaged with the HiFlowTM .

Find out more

- Low footprint as compared to traditional clarifiers

- Easy installation as the unit is delivered fully assembled

- Modular arrangement with capacities ranging from 5 to 150m3/h in a single unit

- Integrated sludge hoppers

- High level of sludge compaction

The HiFlowTM lamella separator is a high rate solids separation process that has 1/10th of the physical footprint as compared to conventional circular clarifiers. It is used as a primary and secondary clarifier in sewage, primary clarifier in water treatment and primary clarification of industrial wastewater.

Hydroflux Epco have extensive expertise and references for clarification/lamella technology as follows:

- Over 330 clarifier systems manufactured since 1962

- Highly effective plate pack surface area

- All stainless steel lamella pack construction

- Robust construction with proven sludge removal systems (VeeMax®, LogMax® and HeadMax®)

- Laminar flow conditions

- Free standing design in steel construction

- Concrete tank designs for larger applications

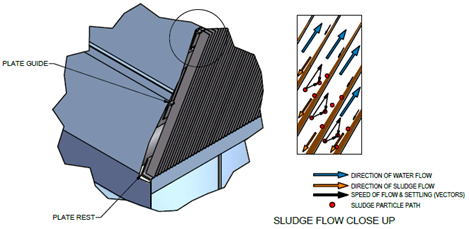

A series of inclined lamella plate packs are used to increase the effective surface area of the unit and to overcome hindered settling.