Effluent Disc Filters

The RoDisc® Rotary Mesh Screen is one of the HUBER range of high quality German manufactured screens and has been designed specifically for the separation of very fine suspended material within municipal and industrial applications.

The RoDisc® Rotary Mesh Screen is an efficient and economical solution in order to achieve tertiary separation up to a virtually solids-free effluent.

The RoDisc® Rotary Mesh Screen has been designed for fine screening of up to 1500 m³/h with a mesh size down as small as 10 μm.

Combined with preceding precipitation and flocculation a micro screen provides a quick and easy-to-implement means for the reduction of phosphorus in effluents to very low concentrations. This prevents eutrophication of waters and excessive growth of algae and water plants.

Find out more

The modular screen design allows for easy retrofitting of additional filter surface areas to meet the ever increasing throughput requirements. For example within municipal applications with preliminary screening and preceding biological treatment a throughput capacity of up to 1500 m³/h can be achieved with 20 filter discs.

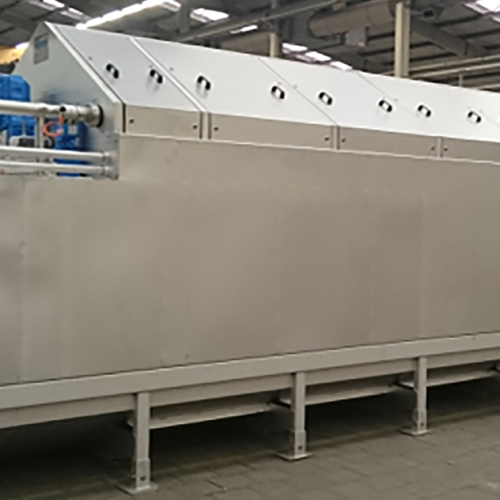

The screen is especially suited for applications where a very high filtrate quality and large filter surface area is required. Due to its small space requirement and modular design the RoDisc® Rotary Mesh Screen can be tailored to suit any specific site requirement

High hydraulic loads, insufficient tank depth and poor settling behaviour of the activated sludge are the most common causes for the poor performance of secondary clarifiers. Frequently, secondary clarifiers are even unable to reliably ensure the solids retention required. Under storm conditions for example, the amount of filterable solids can be up to three to four times the volume experienced under dry weather conditions. Overflow of flocks increases COD, BOD and phosphorus loads in the effluent and receiving watercourse with the result of higher wastewater fees.

Especially the increased concentrations of nutrients in surface waters, such as phosphate and nitrate, lead to eutrophication of water bodies and excessive growth of algae and water plants.

A subsequently installed micro screen is a quick, efficient and economical solution in order to achieve further separation up to a virtually solids-free effluent. Combined with preceding precipitation and flocculation a micro screen provides a quick and easy-to-implement means for the reduction of phosphorus in effluents to very low concentrations. This prevents eutrophication of waters and excessive growth of algae and water plants.

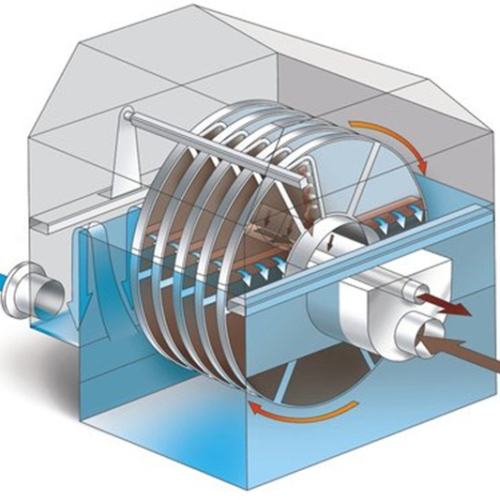

The RoDisc® Rotary Mesh Screen works on the basis of the well-proven drum filter principle. The wastewater to be treated flows through the filter discs from inside to outside. The filter discs remain in rest position at first during the filtration process. The solids are retained on the inner disc surfaces, which leads to gradual blinding of the mesh, resulting in an increasing pressure differential.

An overflow weir ensures that the water level in the tank remains virtually constant. The upstream water level rises as the blinding process progresses. When the predefined maximum pressure differential has been reached, the solids are removed automatically from the filter surfaces.

The solids are removed by the slow rotation of the filter discs combined with spray nozzle bars which wash the filtrate through the mesh from inside to outside without the need to use fresh water. The spray water and the solids contained are collected in a trough and discharged axially from the machine. The filtration process runs on continuously whilst the filter discs are being cleaned

- Screening with a defined separation size provided by a square mesh

- Gravity system

- Low headloss,

- High hydraulic throughput capacity

- No external wash water supply required

- Effluent standards are reliably met.

- Reduced wastewater discharge charges

- Reduction of filterable solids, COD, BOD, phosphorus

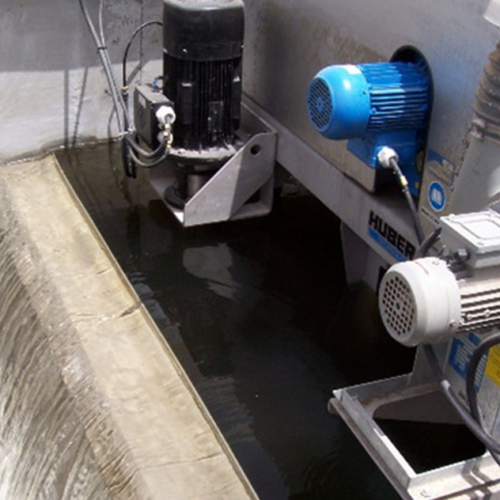

- For installation within a stainless steel tank or in customer’s concrete tank

- Compact, enclosed design

- Continuous operation principal

Micro screening of biologically treated wastewater

The RoDisc® Rotary Mesh Screen is frequently utilised for the separation of fine suspended material from biologically treated wastewater within municipal and industrial applications, especially if secondary clarifiers work insufficiently because they are too small or the settling behaviour of the activated sludge is poor for example. Our micro screens reliably achieve effluent values which are significantly bette rthan the required limit values for filterable solids.

Micro-screening to protect or increase the efficiency of downstream treatment systems.

A virtually solids-free flow is a prerequisite for effective and efficient as well as trouble and maintenance free operation of some subsequent treatment steps, such as UV disinfection or membrane filtration. Our micro screens significantly reduce the concentration of suspended material. Investment and operation costs are more than compensated because micro screening saves money for downstream systems.