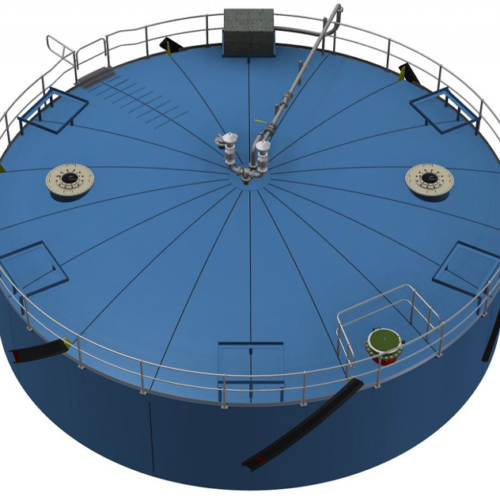

BioCap® Digester Covers

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

The BioCap® is designed to store the waste bio gas produced in the digesters. The cover is also designed to impart a pressure to the bio gas to enable reticulation of the bio gas to the appliances which will utilise the bio gas.

The cover is typically fitted with:

- Sample hatches

- Pressure / vacuum relief valves whose purpose is to protect the digester cover from excessive gas pressure or vacuum conditions

- Flame arrester with weather hood and isolating valve

- Access manholes which allow ingress into the cover gas space during digester maintenance

- Cover height indicator which gives a visual measure of the cover’s position in respect of its vertical travel

- Seal pipes for mounting of sludge mixing lances (not required if external mixing is used)

- Cover movement is detected by ultrasonic level detector

- Bio gas pressure under the cover is monitored by a pressure sensor with high and low adjustable set points

The stored bio gas is prevented from escaping to the atmosphere by a cover water seal system. The cover skirt is permanently immersed in a water bath of sufficient depth to prevent the bio gas pressure exceeding the water depth and thus escaping from under the cover up to a maximum pressure of 500 mm WC. The water seal water is maintained at a set level at all times by constant make up from a header tank fed by a permanent water supply through a ball float valve.